Slotting the forward-pick area of a warehouse

A fast-pick or forward pick area is one from which it is most efficient to pick, but which must be restocked from a reserve or overflow or bulk storage area. Here are some examples of forward pick areas:

- Carton flow rack that is restocked from bulk storage

- The ground floor of pallet rack that is restocked by moving pallets down from higher levels

- Carousels, A-frames, or any other specialized equipment that must be replenished from elsewhere in the warehouse

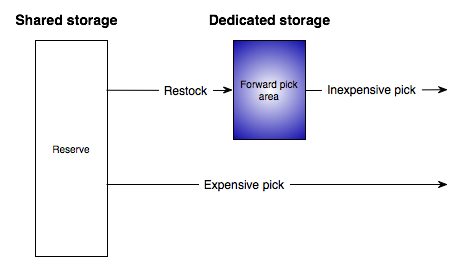

The following schematic shows the flow of material through and

the economics of a forward-pick area.

The forward-pick area is the most important real estate in a warehouse because it is the most convenient from which to pick. Moreover, it may represent considerable capital investment for special equipment. How large should it be? What should be stored there? In what amounts?

To get maximum value from a forward area, one must stock it with the right skus. These are not simply the most popular, because volume-ordered matters as well. A sku that is ordered in larger volumes will have to be restocked more frequently than a sku that is of identical popularity but ordered in smaller volumes. To minimize labor costs we must account for both picking and restocking.

Almost all warehouses store product in the forward pick area according to one of two philosophies:

- Give each sku the same amount of space; or

- Store the same time supply of each sku (for example, store 3-weeks supply of each sku)

You may be surprised to learn that these are equivalent in that they require the same total work (restocks) to maintain the foward pick area—furthermore, you can do better, sometimes much better!

Our book shows how to minimize total labor (picking plus restocking) by careful choice of what to store in the forward-pick area and in what quantities. Furthermore, these models have been realized in software that you can run from their respective web pages.

Computer programs

There are three programs: One is specifically for storing pallets and other unit-loads (which require a different model of labor). The other two are for storing less-than-pallet quantities.

- To slot pallets

- Use this to optimally slot skus into the ground floor of pallet rack or into pallet flow rack. This program is specifically for pallet or other unit-load storage.

- To slot cartons and/or pieces

- Use this to slot skus into carton flow rack or bins or shelving. This program will handle only a single forward-pick area but it accounts for all detail, including the geometries of storage containers and shelves. It will determine the best shelf heights and will show exactly where every carton should be placed: in what orientation, how many lanes, and high they should be stacked.

- To allocate SKUs among multiple types of storage

- Use this to decide which skus should be picked from flow rack, which from carousels, from shelving, bulk storage, etc. This program is most appropriate for high-level design: It tells from which storage mode each sku should be picked. (but it does not tell exactly how to arrange the shelves because it has no model of geometry).

What sets these programs apart

- The programs are provided as services over the internet and so you always have the latest version, and with no need to worry about installation.

- Your data stays on your machine. The computational engines come to you.

- The slotting is computed by mathematical optimization rather than simplistic rules. Furthermore, the mathematical models and optimization technologies are fully documented in our book.

- The programs are fast: Once you have the data, they will compute optimal slotting strategies within seconds, even for tens of thousands of skus. This enables you to quickly evaluate alternative designs.

- After running the programs, the economics of each decision are fully auditable, so that you can understand exactly why the optimization engine made the choices it did. No mysteries.

- You may use these programs freely, but please note that the user assumes all responsibility. See the accompanying license and disclaimers

When to use the programs

These programs will be essential if you are reorganizing your warehouse or part of it or if you are buying new storage equipment. They can also suggest incremental adjustments that you can use as regular maintenance.

How to use the programs

You start each program by clicking on a button on its web page (but the program runs on your computer and your data remain on your computer).

The basic steps of use appear as numbered tabs in each program and are as follows.

- Load a table of sku descriptions.

- Describe the labor economics (estimated costs of picking, restocking).

- Start the optimization.

- Examine summary statistics.

- Examine and save the detailed results.

The most time-consuming part of using these programs is getting the required data.