Assigning skus to multiple storage modes

From which storage mode should each sku be picked?

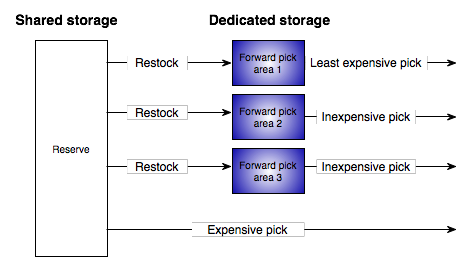

A fast-pick or forward-pick area is one that is convenient to pick from but which must be restocked from a reserve storage area. For example, one forward-pick area might be carton flow rack that is restocked from a bulk storage area; another might be shelving and a third carousels. Each has different geometry (dimensions of shelf openings) and each has different labor economics (typical rates of picking from and restocking to), as suggested by the figure below.

Which sku should be picked from which storage mode? And in what quantities should they be stored? This program computes the answer to that question: It tells you exactly how much of each sku should be stored in each storage mode so that total labor—picking plus restocking— is minimized.

This program is specifically designed to allocate skus amongst multiple forward pick areas. It can achieve this only by ignoring geometry of storage and of skus. Accordingly, it suggests a storage mode for each sku and a volume to be stored; but it does not tell exactly where to place the sku on a shelf. Use the companion program to provide detailed slotting that accounts for all geometry plus additional concerns such as golden-zoning, product grouping, and so on.

Run it from here!

Please read the license and disclaimer, then click to launch the latest version via Java Webstart:

Recent changes to the Java security model and to the Georgia Tech server may require that you to give explicit permission to run programs from the Georgia Tech site. Here is how to do that:

- On PCs this needs to be done only once: Open the Control Pane; on Macs, open System Preferences. Then, on either Mac or PC, select the Java Control Panel and click on the Security tab. and then on the button “Edit Site List”. Finally, add https://www.warehouse-science.com to the exception site list.

- In addition, if you use a Mac, you will have to do the following each time you use the program: Go to System Preferences and select Security. Change the setting “Allow apps downloaded from:” to “Anywhere”. (Be sure to change it back after running the program.)

These instructions work with all browsers except possibly Internet Explorer, so you will have to use an alternative such as Firefox, Chrome, or Safari. And should the program not start automatically, locate the jnlp file in your Downloads folder and open it with Java Webstart.

Also note that some company firewalls may still prevent Java Webstart programs from running, in which case see your system administrator.

You must return to this page and click on the button again each time you want to run the program. The first time you run it, Java Webstart downloads the program files to your machine. Thereafter, it will first download any available upgrades before starting the application. If there have been no upgrades, the application will start immediately.

Need Java?

This program is written in Java so it runs on any of Windows, Mac OS 10+, or Linux. If you do not already have Java installed, get the latest version of the Java Runtime Environment (JRE) here.

Distinctive features of the program

What the program does

This program tells you from which storage mode each sku should be picked, and in what quantity it should be stored, so that the total labor costs (picking plus restocking) are minimized. It can do this because it is based on an integrated model of labor and it incorporates a powerful optimization engine customized to this problem.

Because it optimally assigns skus to storage modes, this program can be used to evaluate design alternatives. For example, you can compute exactly how much labor might be saved by using more flow rack and less shelving.

How the program does it

This program is based on mathematical optimization documented in our textbook Warehouse & Distribution Science

When to use the program

This program will be most useful if you are committed to reorganizing your warehouse or doing a greenfield design. Use this program first, to suggest which skus should be picked from which storage modes; then use the companion program to compute details of the slotting.

How to use the program

The basic steps of use appear as numbered tabs in the program, which will help you follow the numbered steps:

-

Load a table of sku descriptions. This should be a tab-delimited text file presenting a table with the following fields:

- Unique sku ID

- Number of times this sku was requested

- Quantity requested (number of pieces/eaches/units)

- Case pack (number of pieces in a storage container/carton/bin). The case pack may be 1, in which case the piece is the same as the storage container.

- Length of a storage container (eg carton)

- Width of a storage container

- Height of a storate container

Here is a sample on which to practice.

-

Load a table of descriptions of the storage modes. This should be a tab-delimited text file presenting a table with the following fields:

- Unique ID of the storage mode (eg its name)

- Volume of usable storage space in the mode. The linear unit of measure must match that of the table of skus. For example, if you give carton dimensions in feet, then you must give the volume of the storage modes in cubic feet.

- Average cost-per-pick expected from this storage mode, in person-minutes

- Average cost-per-restock expected from this storage mode, in person-minutes

Note that reserve/bulk storage is not restocked from within the warehouse and so is given a cost-per-restock of 0. Also, because it typically uses shared storage, you will want to list its available volume as “Indeterminate”.

Here is a sample on which to practice.

- Start the optimization.

- Examine summary statistics.

- Examine and save the detailed results, which will tell you where every sku should be stored and in what amounts.

The most time-consuming part of using this program is getting the required sku data. Once you have the data prepared, the program will compute optimal slotting strategies within minutes, even for tens of thousands of skus.