This is a project to accompany the course and

the book Warehouse & Distribution Science, at the

Georgia Institute of Technology, by John J. BARTHOLDI, III and

Steven T. HACKMAN. Everyone is welcome to use the book and

materials for educational purposes, as long as all copyrights

remain intact.

The company and its DC operations

We are pleased to welcome back S. P. Richards Co., for whom

previous classes have done projects. Rick Weeks and Amy Severance

of SPR visited on 27 January and described the company and some

engineering goals at the Philadelphia distribution center. (Their

presentation is available here in

ppt (3MB) or

pdf (32 MB) formats.)

Here are highlights from the talk. SPR distributes wholesale

office products. Each DC accepts orders until around 5PM (depending

on the DC and the customer) and ships overnight for next day

delivery. The customers are known and stable but their orders are

not known until shortly before they must be loaded onto a scheduled

truck for delivery.

SPR serves three main types of customers: "Mega-dealers",

independent resellers, and internet resellers (the last of which is

growing quickly). About 75 percent of orders received by SPR are

"wrap-and-label", which means they are packaged as if they came

from SPR's customer.

We will be looking and the distribution center in Morristown,

NJ, which serves the Philadelphia area and so is informally called

the "Philadelphia DC" or, even more informally, the "Philly DC".

The Philadelphia DC has long been one of the most efficient of the

SPR DCs. But recently their productivity has dropped slightly after

they installed a warehouse management system. They are now

searching for how to regain the lost productivity.

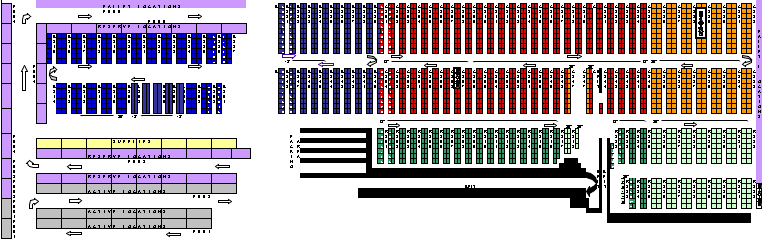

We will be focusing on the area of the warehouse shown in the

figure below. (You can find a larger version of this layout

here.)

Most of the activity in Philadelphia is in zones B and C. Zone B

is the blue shelving in the figure above and this is the primary

picking area. The cluster on the left is 30-inches deep and

42-inches wide. The cluster on the right is 18-inches deep and

42-inches wide. Zone B was intended to hold the fastest moving of

the small products. Zone C is the red shelving, some 18-inches

deep, others 30-inches deep, and all 42-inches wide. Zone C was

intended to hold slower moving small products. Currently zones B

and C are picked independently of each other and the two

corresponding parts of any order are shipped separately. However,

as this has not produced the hoped-for efficiencies, the

order-picking for these two zones will be combined, so that each

picker will travel through both zones if necessary. SPR has been

puzzled that the lines picked per person hour have been

approximately the same in zones B and C. Is this because of wrong

choice of product to store in B? Or because of congestion? Or is

there some other reason?

Zone F is pallet rack that has been configured to hold both full

pallets and, in some locations, cartons. Zone F is the gray racking

on the bottom left of the figure and also the purple racking that

encircles zone B in a sort of horseshoe shape. The gray area of

zone F is for active pick locations of products that are stored and

picked as eaches, such as brooms or garbage cans. The purple region

is intended to hold overstock for zones F and B but it also holds

some other items that are both stored and picked as eaches.

Here is a legend for the map above:

- The blue area is Zone B. The lighter blue is 30-inch shelving

and the darker (navy) blue is 18-inch shelving.ÊThe top shelf

is reserve.Ê (The reserve locations on the top shelf always

use Shelf/Level = T and Position = T so that they are

distinguishable in the database by the name.)Ê The other

locations are active picking locations.

- The purple area is Zone F reserve locations and the gray is

Zone F active picking locations. All of Zone F is pallet rack.

- The yellow area is pallet racking used to hold packing and

shipping supplies.

- The red area is 18-inch shelving in Zone C and the orange is

30-inch shelving in Zone C.

- The green are is Zone R. The lighter green represents 30-inch

shelving and the darker green represents 18-inch

shelving.

Other features of interest in the layout:

- The pickup station, where orders are released is the first

yellow bay from the right.

- The dropoff point where completed orders are checked and packed

is at the black conveyors on the left.

Each order-picker pushes a cart and travels a complete circuit

through the main aisles of the zone, picking a batch of orders.

Workers pick directly into final packaging, which is cardboard

boxes. Any full-case quantities are pulled from reserve. Thus if a

customer requests 13 pens and the pens are packed 12 to a carton,

there will be one pick from reserve (of 1 carton) plus one pick

from the active pick area (of 1 pen).

You can take a tour of the key operating areas of the SPR

Philadelphia distribution center

here.

The project

The Philadelphia DC is reported to be among the best in the SPR

system. However they continue to look for ways to improve. They

have generated the following list of issues.

- Slotting

- Evaluate the slotting of Zones B, C. Are the right skus stored

there? The right amounts?

- Propose a better slotting for Zones B and C and their reserve

areas. (Note: we have access to a

commercial

slotting tool that might help with this.) Ideally, the slotting

will put all the reserve for Zone B on the top shelves in Zone B

and in the pallet racking of Zone F. Similarly, all the reserve for

Zone C should be kept on the top shelves of Zone C and in the

pallet racking of Zone R.

- Should SPR stock by vendor so it is easy for stockers to

putaway the product?

The analysis should be conducted under the assumption that any

full-case quantity will be picked from a reserve location (if there

is one). This means, for example, that if a customer orders 15 of a

sku that is packed 12 per case, there will be two pick-lines

generated: One for a full-case, to be picked from reserve, and one

for 3 eaches to be picked from the active pick location. The

full-case will be picked, labeled, and put on the conveyor; the

eaches will be packed with other loose items on the same order.

These two pick-lines might not be put into the same batch.

- Operations

- Should Flow Rack be used in Zone B for fast moving items? Or

some other material handling equipment? (Note: build a careful

analysis of the issues involved.

- Recommend whether to pick to totes or boxes. (Note: This will

require estimating the work to pick and to check/pack in each case.

A simple approach would be just to estimate the space and time

required to accumulate orders, sum over all orders and compare. A

more detailed approach might involve simulation.)>

- Recommend whether or not to separate one line orders and

multi-line orders. (Note: again, this requires estimating the work

required in each case and how this would the flow of completed

orders to meet shipping schedules.)

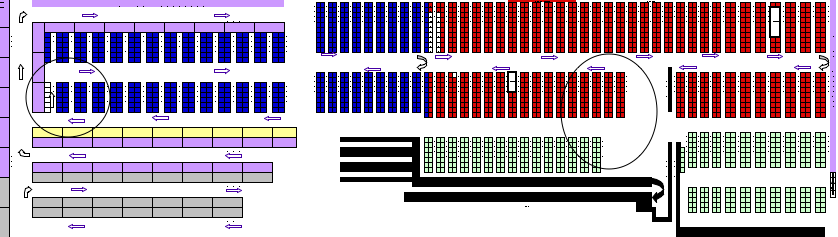

As in any real operation, the warehouse may be changing in some

ways even as we try to improve it. For example, here are two

changes under current study. In the circled region on the left of

the figure below, you can see that one line of shelving has been

removed (formerly blue, now clear) and the pick-path has been

changed to be unidirectional, in hopes of reducing congestion.

Similarly, the circled region on the right might be changed so that

product to the far right of Zone C is moved to the left-most green

area. Then Zone C would be more compact and could be visited by a

unidirectional path, again to reduce congestion. Teams should feel

free to evaluate these suggestions, or come up with your own.

Data

The company data is copyrighted and proprietary. You may

use it for the purposes of this course only. (If you would like to

use it for something else, please contact me to

discuss.)

Data will be posted as soon as we receive it. Here is what we

requested:

- Item master, with the following fields:

- Unique sku ID (text)

- Short text description (text)

- Vendor (text)

- Length in inches of storage container (2 decimal places)

- Width of storage container (2 decimal places)

- Height of storage container (2 decimal places)

- Selling units per storage container (2 decimal places)

- Total number of requests (customer orders) during study period

(1 year?)

- Total number of selling units requested during study

period

- Maximum on-hand inventory (either in selling units or in

storage units, whichever is more convenient)

- Current location(s): Zone, aisle, section, shelf,

position

This will be used to support computation of re-slotting Zones B, C,

and F

- Order history over, say, 3 months, with the following fields:

- Unique order ID (text)

- Unique customer ID (text)

- Date (date format)

- Time received (time format)

- Date released to picking (date format)

- Time released to picking (time format)

- Unique sku ID requested (text)

- Quantity (integer)

- Unique ID of assigned batch

- Size of box assigned to hold order

This will be used to address some of the other questions you

raised, such as about how to batch pick-lines, whether to pick into

a tote or a box, etc. Note that it was important to avoid December

and January in this order history because during those months, and

only then, calendars are the fastest moving items. You must always

be careful of seasonalities!

- Additional warehouse description

- We are to recommend size of shelf openings in Zones B, C. The

distance from the lowest shelf to the top shelf is 100 inches in

Zone B and 93 inches in Zone C. The shelf openings are 41 inches

wide.

- In Zones B and C, we can fill each shelf to the top: No gap is

necessary. It is okay to allow product to overhang a shelf by up to

one inch.

- Sizes of boxes into which orders are picked (in inches):

11x8x4, 17x12x12, 17.25x11.25x9, 14x11.5x6.

- The standard pick-cart is 58 inches long and 27 inches wide.

The opening between the bottom and middle shelves is 19 inches

high; and the opening between the middle and top shelves is 20

inches high.

- Labor economics

- Picking

- The approximate pick rates in Zone B and Zone C are both

currently about 60 lines per person-hour. (SPR hopes to increase

this to 90-100 lines per person-hour

- To pick from active locations in Zones F (gray region) or R

requires about 34 seconds per pick. To pick from reserve locations

in F (purple region) or R requires about 74 seconds per

pick.

- Restocking

- To restock a Zone B active pick location from Zone B Reserve

(top shelf) requires 45 seconds on average. From looking at the raw

data, the replenishment takes longer if the user has to walk from

one aisle to another (if the reserve is not in the same aisle as

the active location). Also, if the reserve is more than one bay

away from the active, this pushes the times up also.

- To restock Zone B from Zone F involves the following steps..

- To pull from F zone requires about 3.67 minutes per sku.

- To putaway to B zone requires about 2 minutes per

sku.

- To restock Zone C from Zone R or Zone B from Zone R requires

two steps.

- To pull from Zone R requires about 30 seconds.

- To putaway to Zone B requires about 27 seconds.

- To putaway to Zone C requires about 30 seconds.

Thus a replenishment from R to C would require about 60 seconds per

carton and a replenishment from R to B would require about 57

seconds per carton.

Here is what we have received so far. Note that in each instance

we have tried to err on the side of requesting too much data rather

than too little.

- An Excel spreadsheet (1.5MB)

with all of the cases that are in reserve locations for zones

A,B,C,R,F,W. (This includes all zones, in case there is overstock

for items in B,C, or F.) Here is what the fields mean:

- Case: The unique case id for each box

- SKU: The unique SKU in the box. Mixed cases in reserve

are not allowed. So there should only be one record per case ID.

(Please report if you find otherwise.)

- Quantity: This is the quantity in the box (in selling

units). If the quantity is equal to the standard case quantity

(which will be provided in another file), then the reserve location

has a case ID on every box. This is what SPR refers to as a "case

reserve" location. If the quantity is a multiple of the standard

case quantity, then the reserve location has just one case ID for

an entire pallet. This is what SPR refers to as a "pallet reserve"

location. If it is not either, then someone has put a partial case

in reserve, which they are not supposed to do, or the standard case

quantity is not correct. Note, the standard case quantity is what

SPR calls the "number of selling units per master case". In

reserve, SPR stores only master case quantities. There are no open

boxes.

- Zone, Aisle, Bay, Level (shelf), Position: The

definition of the reserve location

- Location Type: This also indicates whether a location

is a Case Reserve or Pallet Reserve location. BLU and KCN are codes

that refer to a Case Reserve location, with a case ID on every box.

PLC and PLP are Pallet Reserve locations, where pallet quantities

are stored with a case id for the entire pallet quantity. Note that

for PLC locations the users can pull boxes off a pallet, just

reducing the amount assigned to the case number. For PLP locations,

we pull only full pallets. There are no broken pallet quantities.

These are only for the few items that we sell consistently by the

full pallet.

- An Excel spreadsheet

(0.6MB) with all of the active locations in all zones (again, more

data than we may need). There should only be one location per SKU

and one SKU per location. The fields should be self-explanatory.

The quantity is the current quantity, in selling units, that exists

in the active location as of 01 February 2005.

- An Excel spreadsheet

(1.3MB) with status and dimensions of the skus. Dimensions are

given for both eaches and for cartons but also, in many cases, for

an "inner pack" as well. Recall that this is a packing level

between the carton (case) and the each (selling unit). For example,

Pens are sold by the each but come packaged in inner packs of 12;

and the inner packs come in cases of 12 inner packs (144

eaches).Ê Mostly, SPR does not use the inner pack information

but it might be useful to us in those instances when case

information is not available. The fields are mostly

self-explanatory:

- Stocked: Possible values are Y (yes), N (no and may be

ignored, or X (new item that will be stocked but has no sales

history)

- OMS status: Possible values are A (active), or D or X

(discontinued) or P (purged). All skus marked D, X, or P may be

ignored.

- SellingUOM: Selling unit of measure.

- SelLen, SelWid, SelHgt, SelWgt: Length, width, height,

weight of the selling unit in inches and pounds

- ShipSelling: Possible values are Y (Selling UOM is a

corrugated box that can be labeled and shipped without

repacking

- Inner1Qty: The number of SellingUOM's in an inner

pack

- Inner1Len, Inner1Wid, Inner1Hgt, Inner1Wgt: Length,

width, height, and weight of the inner pack, in inches and

pounds

- Case Qty: The number of SellingUOM's in a case

- CaseLen, CaseWid, CaseHgt, CaseWgt: Length, width,

height, and weight of a case, in inches and pounds

- Additional sku data in the form of a

text file (1.6MB). This

data complements (and, in some ways, duplicates) the previous. New

fields include:

- Vendor ID: From whom the item is purchased

- Hazmat Code: Whether item is hazardous and so requires

special handling. May be ignored.

- Selling UOM:

- Stocking Status:

- Item Status:

- Selling UOM Length, Width and Height: in inches

- Case UOM Length, Width and Height: in inches

- Selling UOM/Case:

- Quantity Ordered: Measured in selling units

- Lines Ordered: That is, picks, requests

- Max Order Size: Most units on an order-line

- Average Order Size

- Max Case Order: Most number of cases on an

order-line

- Average Case Order: Averaged over all order-lines

requesting at least one case

- Case Lines Ordered: Number of lines for at least one

case

- Max Order No Case: The maximum quantity on a line for

lines that were less than a case

- Average Order No Case: Average line quantity for those

lines that were less than a case

- The last columns display amounts on-hand. There are two columns

for each month. The AVG column is the average of the inventory

levels over all days of the month. For example, "janavg" gives the

average inventory levels over the days of January 2004. The OH is

the inventory level on the last day of the month. For example,

"janoh" gives the inventory level on 31 January

2004.

- A spreadsheet containing

"min" and "max" values for the sku in each active pick location.

The warehouse management system triggers a replenishment to any

location for which the number of pieces (eaches) has fallen to the

min value; and the replenishment is sufficient to bring the

inventory level at that location up to the max level.

- A sales history (text file;

59MB) containing the following fields:

- item: Unique sku ID

- vnid: Vendor ID

- itdesc: Text description of sku

- ordnbr: Unique ID of this order

- linenbr: Number of the line in this order

- cusnbr: Unique ID of customer

- ordqty: How many selling units ordered

- shipqty: How many selling units shipped (may be less

than ordered if, for example, out of stock. Should never be

more.)

- uom: Selling unit-of-measure

- txndate: Order data and time

- A snapshot of the batches

that were formed by the warehouse management system (2.6M) for

assignment to a particular truck (picking cart). Among other

things, this contains the Truck Nbr, which is the unique

batch number. It also contains the unique ID of the carton for

which each pick-line is pulled. There are two accompanying tables,

the Carton Header File (0.8M) and

Carton Detail File (2.8M).

Here is a key to the fields of

these files.

Suggestions for getting started

- Prepare the data: Organize it. Perform consistency checks.

Identify missing or inconsistent data and develop a plan for

handling them (Fix? Ignore?).

- Profiling warehouse activity in the zones of interest to us:

What are the most popular skus? What are the most popular vendors?

How much space is devoted to each sku and to each vendor? What is

the distribution of lines-per-order in Zones B and C? How many

picks come from each zone? How many picks come from reserve

locations and how many from active pick locations? Which sku's have

reserve locations and in what zone?

- Prepare a visualization of which aisles are most visited. For

more detail, prepare a visualization of which sections of shelf are

most visited.

Here

is version 0.1 of a tool to generate such a visualization. (Note:

It would be helpful and not hard for you to adapt this tool, make

it more general, and provide more adequate documentation. Making

this tool more generally useful could be a significant contribution

even though it does not directly address the client's issues.)

- Has SPR chosen the correct skus to store in the fast-pick area

and the correct amounts? Use a spreadsheet to check this via the

fluid model.

- If a fast-pick area seems a promising idea, use

commercial

software to slot it and the reserve area.

- Finally, do not work only on slotting. This is a complicated

issue at SPR. (It might be valid to conclude that a fast-pick area

offers them too little benefit for the complexity of design and

maintenance.) Do not lose sight of the big issue: How can

pick-rates be increased?