Chris del Percio, Manager of Warehouses, supports over 500 Wawa Convenience Stores out of his facilities in Wawa, PA. He reports success in picking full cases to pallet jack in a union shop. During the first week the order-pickers averaged 25% improvement in pick rates and hit 52% improvement by the first Friday.

Chris and his team implemented this entirely on their own.

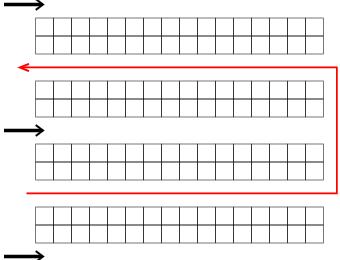

All picking is from pallets stored on the floor. Originally each of the 4-6 workers walked through all the aisles, picked cases, and built a pallet for a customer. Switching to bucket brigades allowed Wawa to use narrow aisles without congestion because there is no passing under bucket brigades. Narrow aisles also freed up space for two additional aisles.

|

|

|

|

|

Chris reports that there was some initial resistance to handing off partially completed pallets because each worker tended to have his own style of pallet-building.

To avoid losing time due to occasional blocking, a worker may abandon a pallet-in-process and go back to get another, but if more than one or two pallets are sitting, this is a sign that something is wrong.