Figure 2: After bucket brigades the work-in-process disappeared, which relieved congestion.

Figure 2: After bucket brigades the work-in-process disappeared, which relieved congestion.

Figure 1: Before bucket brigades there was congestion due to unavoidable imbalance in zone-picking.

Our first implementation of bucket brigades was at the national distribution center of Revco, in Knoxville, Tennessee. (Revco was subsequently absorbed by CVS.)

Like many distribution centers supporting retail sales, Revco/CVS runs multiple independent pick lanes of flow rack, pick-to-light. All totes must maintain sequence so that they arrive at shipping in reverse order of delivery; and so Revco initially did zone-picking, with zones based on a work-content model built by an industrial engineer.

Prior to bucket brigades, Revco/CVS had problems with productivity because they had to rely so heavily on temporary workers and on overtime during their busy season. Temporary workers can be as expensive per hour as full-timers; but they are not as productive. Revco/CVS partitioned work into zones based on the assumption of identical workers; but the pick rates of its workers could vary by a factor of three. The result was that the allocations of work were always unequal and so the pick lanes were imbalanced: The slowest pickers were frustrated at not being able to keep up and the fastest pickers were underutilized. To make matters worse, Revco/CVS had adopted a policy of putting the fastest worker first in the pick lane so that she could keep the lane full of work. Unfortunately, this created congestion that increased the opportunities for putting product in the wrong tote. (See Figure 1.)

We explained the idea of bucket brigades to the workers in about fifteen minutes one morning, and away they went. Bucket brigades immediately reduced work-in-process, which relieved congestion on the conveyor. This increased pick rates and accuracy because workers could more easily put the product in the correct tote (Figure 2).

An additional benefit was that supervisors could more easily compare the relative progress of different lanes and move workers as necessary to keep the lanes coordinated (to reduce sorting downstream). Bucket brigades also made it easier to move workers from a fast lane to a slow one because there is no need to redefine zones.

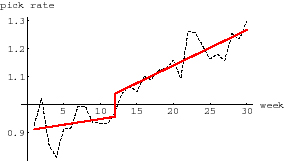

Figure 3: Revco/CVS measured a 34% increase in pick-rates after changing to bucket brigades.

The most dramatic result was an increase in pick rates. Figure 3 shows the weekly average pick rates measured by Revco/CVS over most of a year (normalized to Revco's work standard 1.0). You can see that prior to the introduction of bucket brigades, Revco was picking at about 95% of their own work standard. After bucket brigades, this rose to 134% of their work standard.

As an incentive, Revco/CVS offered each brigade $0.60 of each $1 they saved (in addition to their regular wages). The incentive was to be split equally among the members of the brigade. This seemed to help the team members focus on team productivity.

We observed an interesting event after about two weeks: The slowest member of one team was so much slower than her fellows that she rarely was able to proceed beyond the first bay of flow rack. At the end of one day, the other pickers came to management and asked that she be removed from the team because they could pick just as fast without her and could then split the incentive among fewers workers. Bucket brigades tend to make it clear who is contributing and who is not and this tends to reduce disputes. Other work was found for the slow worker.

Revco was not unionized.

After buying Revco, CVS has extended the use of bucket brigades to all of the original CVS distribution centers.